IDEAL STORE LAYOUT

Choosing an Ideal Store layout

There are several critical characteristics that must exist in a restaurant and a trade area for a restaurant to be successful. To ensure that proper restaurant sites are selected, following points must be considered:

- Trade Area Qualifications: A sufficient number of households with the desire and means for buying delivery orders

- Restaurant Characteristics

- Demonstrated executional ability

- Solid management staffing

- Rider availability

- Restaurant capacity

- Production efficiency (5-7 minute packing times)

- High thru put

- Site Characteristics

- Quick entrances and exits to and from your parking lot

- Adequate parking space to meet requirements of delivery riders and your current business

Consider the impact of various site elements on your delivery service.

IDEAL STORE LAYOUT

Key Site Elements |

Impact on Delivery Services |

Entrances and Exits |

Quick street access into and away from the restaurants is critical to meet the objective of delivering within 30 minutes. |

Parking lot maintenance |

Ensure that the lot is free of potholes, snow and ice. |

Parking |

|

Building and Security |

Consider the effect of the existing site conditions and safety of the surrounding neighbourhood. |

IDEAL STORE LAYOUT

Guidelines for rider/driving parking

Required Spaces |

||

#Riders on Duty |

Peak Volume |

Before/After Peak |

1-2 |

1 |

2 |

3-4 |

2 |

3 |

5-6 |

3 |

4 |

7-9 |

4 |

5 |

Assumptions:

- Correct number of riders are on duty.

- At peak volume, half of the riders will be away from the restaurant on delivery at all times.

- If your store has mix of bikes and cars, please plan for parking space accordingly

Basic Rules of layout

- Make sure your restaurant has linear flow.

- Linear flow is the efficient flow of production areas in a line from station to station, with no interruptions or crossovers.

- True linear flow would be difficult in most cases because of the space required and the number of steps a Team Member would have to take when minimum staffing is used.

IDEAL STORE LAYOUT

- However, by "bending" the concept to fit your needs, you can still achieve the benefits.

- Work toward a production flow that allows your Team Members to pivot, rather than step, to accomplish their job.

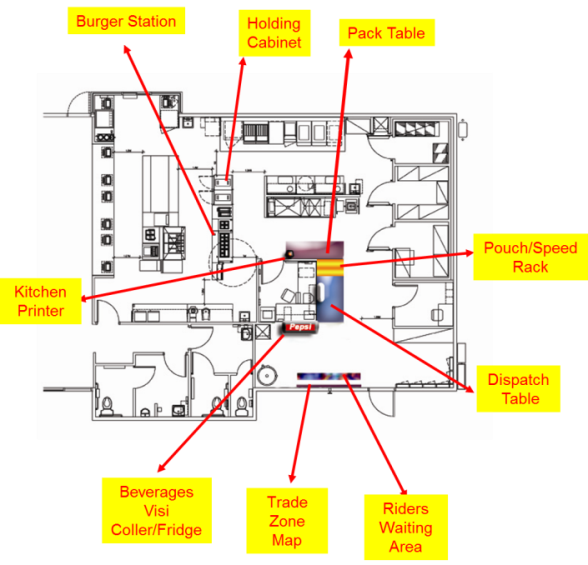

- Make sure your dispatch station is near the map/beverages and door

Layout Considerations

- Consider constraints such as building layout, Fryers’ position, and load-supporting walls.

- If capital is not readily available, plan to make the changes as you can get funding.

- Check with your Area Coach or Franchise Operator before purchasing any additional equipment or supplies

Other Guidelines:

- If the width of the restaurant permits, place the speed rack perpendicular to the dispatch area.

- Locate dispatch station near the beverages at the end of the flow.

- Post maps next to dispatch and beverages

- Keep beverages close to the door.

IDEAL STORE LAYOUT

Benefits of correct layout are

- Maximises efficiency and productivity

- Improves service times and consistency

- Reduces fatigue of team members during shifts

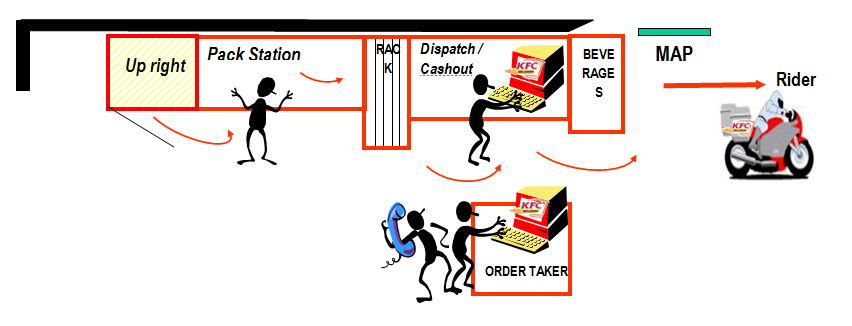

Example of how to incorporate Delivery in a KFC store: This set up considers that the market has a Call Centre

IDEAL STORE LAYOUT

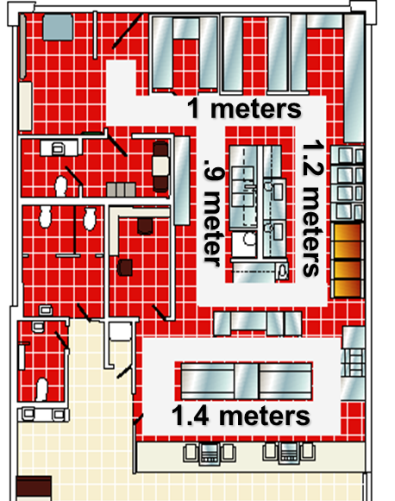

All aisles need to be clear and allow team members to pass each other without interference

- Service counter aisles should be 1.4 m wide

- Raw material storage aisles should be 1.0 m wide

- Production aisles should be 0.9 m wide with exception of aisle between breading and cooking, it should be 1.2 m wide for fire regulations

IDEAL STORE LAYOUT

Three dimension modelling for workstation

In order to view the three dimensional model of a delivery store layout, please follow the following process:

- You have to download and install Googlesketchup software to view the 3D model. It is free and can be downloaded from this link : Download

- Click here to download 3-D Model 3-D Model. Open this file with help of Googlesketchup software

IDEAL STORE LAYOUT

Capacity Calculations

- How to calculate requirement of delivery bags / pouches : Use the following formula to calculate how many pouches you need Terminologies:

- Drive time per dispatch : To and fro time from store to customer and back

- No. of dispatch in one hour: 60 min / average time per dispatch

- Total number of dispatches in peak hour : Peak hour delivery / transactions

- How to calculate requirement of riders:

Formula : Peak hour delivery transactions in one hour divided by no. of dispatches in one hour times 1.5

Example:

Average drive time per dispatch = 20 min

No. of dispatches in one hour = 60 min / 20 = 3

Peak hour delivery transactions = 30

Total number of dispatches in peak hour = 10

Number of pouches required : 10 x 1.5 = 15

Note : Plan for 1.5 times the number of dispatches to take care of big orders and back up

Formula : No. of delivery orders at peak hour divided by average number of orders delivered per peak hour

Example:No. of delivery orders at peak hour = 48

Divide by 4 (average number of orders delivered per peak hour)

Riders needed at peak hour = 48/4 = 12

IDEAL STORE LAYOUT

- How to calculate requirement of bikes :

- How to calculate how many terminals/ telephone lines/CSRs are needed (for in-store order taking/ call centre) :

- Peak hour orders = Total number of delivery orders for the highest volume hour of the week

- Calls to order ratio = Total number of calls versus orders. Example: 1.3 means that every 1.3 calls result in 1 order being placed.

- Time per call = Average length of each call including greetings, questions, order placing, and wrong numbers. This number can be obtained from the phone company. Express this number in seconds, such as 120 seconds.

- Delay between calls = What is the average time lapse between each call? This number can be obtained from the phone company. Express this number in seconds, such as 12 seconds.

- Peak hour orders x calls to order ratio = Total number of calls for 1 hour

Formula : Peak hour bikes : The number of riders x 1.25

Example:

Riders required = 12 (from above)

Bikes required = 12 x 1.25 = 15 bikes

Note: Markets can decide their multiplying factor keeping in mind – breakdowns, peak business and sales planning.

Terminologies

Formula:

IDEAL STORE LAYOUT

- Total number of calls for 1 hour x (time for call + delay between calls) / 60 = Total number of minutes needed to answer these calls

- Total number of minutes needed to answer these calls / 60 = Total number of lines/terminals you need

Note: Plan for extra phone lines. This allows a customer to be placed on hold rather than to get a busy signal.

Example :

100 orders x 1.3 calls to order = 130 calls

130 calls x (120 + 10 seconds)/60 = 16900/60 = 282 minutes

Terminals needed : 282 / 60 = 4.7 ~ 5 (rounded up)

Add 2 to this number to get number of phone lines. In this case,

Phone lines required : 5 + 2 = 7

Note: As you introduce Delivery in your store, it is important to know that your sales will increase, hence you need to re-look at how you man each station to cope with the extra demand. Prepare deployment templates as quick reference for labour planning.

- Calculation of CSR requirement:

In order to ensure adequate number of CSR’s are scheduled for the shift and the peak hours, it is important to understand the component of a call. In general each time our CSR in stores receive a call the following activities will take place.

IDEAL STORE LAYOUT

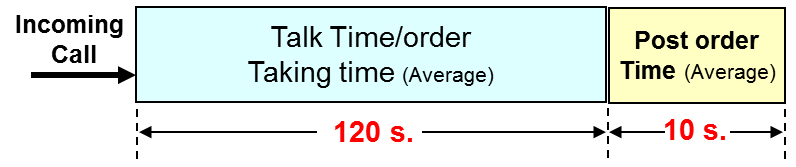

Talk time or order time : The time taken from the moment that customers call is answered, till the time that the conversation ends. From best practices around the world it is understood that the Average talk time is around 120 seconds.

Post order time, or Wrap up time is the time that the CSR may spend finishing the order, prior to sending it to printers or prior to being able to answer the available call. From best practices around the world this estimated to vary around 10 to 15 seconds per call. Obviously, the best way is to ensure that we reduce this post order time to minimum possible, if not eliminate completely.

The other type of calls that we receive a lot of are Question call or Follow up calls. These calls are made by the customers to ask a question or get an address/phone number of one of our stores or follow up on their orders or change something in their orders. These calls are also unavoidable unless your system prompts them to use a different number for queries and should be considered when scheduling for CSR’s.

Lastly, there are those nuisance calls, referred to as Hoax calls. These calls classified as those usually made by kids who want to have a moment of fun. These will increase during school holidays or in the afternoon, when perhaps the parents are not at home. These calls too take time away from your Order Takers and Agents and need to be considered when scheduling. As we can see, they are a lot other factors that needs to go into considerations when we are preparing schedule for our Order Takers and agents.

Based on the learning’s from last page it is not adequate to just go by the number of transaction anticipated for each hour and prepare the schedule for the CSR’s. A better measure is the number of calls anticipated for each hour and then use that as the bases for number of CSR’s needed for each hour. Based on the research from various international call centers and considering all the inefficiencies described in the last page if we wish to answer at least 90% of the calls within 30 seconds or before the 4th ring , we need to assume 3 minutes per call, for each call received by the CSR, regardless if the call was an order or just a query. Based on the above assumption, one CSR can only handle 20 calls per hour.

IDEAL STORE LAYOUT

Important Question: If your store anticipate to receive 40 calls at its peak hour, based on the above assumptions above that one CSR can take 20 calls per hour, would it be adequate to Schedule 2 CSR’s to handle the volume for that peak hour and still manage to answer at least 90% of calls before the 4th ring or in 30 seconds? Answer: NO

This would have been true if calls arrive two at the time and the next calls only arrive when the last call was ended. We know that this will not happen in reality and there is a good chance that we receive 3 to 4 calls at the same time, every time, hence you need to decide how many CSR you need to achieve your goal of 90% of calls answered before the 4th ring or 30 Seconds and then have enough CSR scheduled for that hour. Based on the data available from leading call center companies, in this situation, in order to achieve your goal of 90% of orders before the 4th ring at your peak hour, it is advisable to consider your talk time to be as high as 3.75 minutes, hence you need 2.5 or 3 CSR at this hour.

Obviously, having 3 CSR will ensure a better service for customers, however, they will have a lower occupancy ratio and it is important to assign secondary tasks to CSR’s to make sure your labour is used efficiently.

To summarize, please use the embedded calculator below to ascertain your requirement.

Calculator – Restaurant Capacity

Calculator – Order Taking Capacity

Click here to download the calculator (excel format) for your reference.

Capacity Tool

EQUIPMENT AND SMALL WARES

Equipment

- Delivery Bag:

- Cold Delivery Pouch :

There are many types of delivery bags from insulated ones to heated ones. Your market must decide the option basis what works for your market both in terms of maintaining product quality until delivery and also cost effective. Sourcing teams in your respective markets would be able to provide more information.

|

|

Click here to download CSL for delivery bag (Vesture Brand) for your reference. Vesture CSL You can customize this CSL depending on the brand used in your market.

With delivery being such an important channel in our market, ensuring we have a delivery option for desserts and ice drinks such as Krushers, Milkshakes and Soda Fountain is essential! KFC cold delivery bags provide a freezer gel inner to ensure we maintain cold beverage temperatures when delivered to our customers

EQUIPMENT AND SMALL WARES

sr No |

Parts of delivery bag |

Function |

1 |

Straw Holder |

Straw holder pocket outside the bag to hold straws |

2 |

Delivery Cup holder with Freezer Gel |

Freezer gel is included in the cold delivery bag to maintain cold temperature. |

3 |

Outer Insulated Bag |

Outer insulated bag helps and supports freezer gel to maintain the temperature of the product. |

4 |

Receipt Holder |

Receipt holder enables driver to carefully carry product receipt. Also benefits in distinguishing orders. |

Small wares:

- Heated Delivery Power Delivery Unit (if your market is using heated pouches)

- Heated Delivery Indicator (if your market is using heated pouches)

- Heated Delivery Element (if your market is using heated pouches)

- Cold Delivery Specialized Frozen Inner

- Delivery Bag Vendor Comparison Delivery Bag Vendor Comparision

DELIVERY VEHICLES & SAFETY KIT

Delivery Vehicles

|

|

|

Rider Protective Gear

|

|

|

Safety Helmet |

Raincoat |

Winter Jacket |

Driver/Rider Safety / First Aid Kit

- Gauze Pad / Sterile Cotton

- Antiseptic Lotion (eg.. Dettol)

- Bandage

- Scissor

- Band Aid

- Antiseptic

- First Aid Tape Roll

- Torch with Flash Light

BEST PRACTICES

Please refer to best practices from markets on sign off process. You may customize these reference documents to include your market requirements. You can download the files from the link below:

Launch Sign-off Checklist Launch sign Off

Launch Sign off Process Sign off Process

Pre & Post Launch Delivery Checklist Launch delivery Checklist