QUALITY & FRESHNESS

Overview:

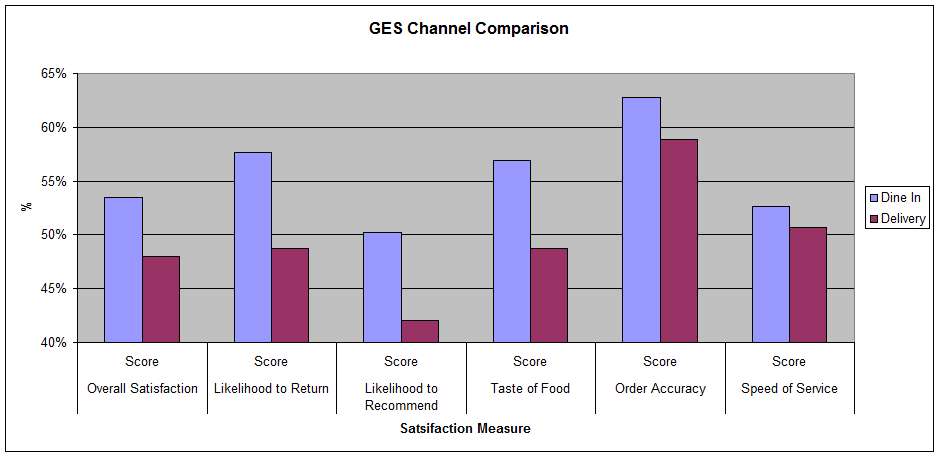

- Delivery can be operationally more demanding than other channels

- GES gives the perfect opportunity to acknowledge where gaps arise

- Particular issue can arise around taste of food – packaging, hotness, moisture and presentation

- As delivery can be more of an occasion (sharing, friends family) and therefore the customer can be less forgiving. This can show itself in ;

- Less likely to return

- Less likely to be completely satisfied

Hence it is very important to ensure that quality and freshness is managed well while we deliver. We have following rigorous processes to ensure that quality (temperature and taste) is validated.

QUALITY & FRESHNESS

Product Validation Check - Temperature

Conducting holding trials

- Conducting holding trials

- It is important to cook enough products so that all testing is completed in one batch for example….. 1 strip will be tested every 25% of hold time and test 4 times throughout delivery bags giving a total required of 4 x 4 =16 (for OR I would recommend we test 1 white 1 dark meat

- Place the product in the coolest part of the holding unit (this will replicate worst case), See diagram below

- Remove product from holding unit as in intervals of 25% of original hold time

- Remove product from delivery bag. Check and record product temperature every 2.5 mins to check that the temperature has not dropped below 63°C. Once product has reached 63°C, this is your Max hold time for delivery.

- The quality of held product to be assessed. Assessment should consist of Taste and appearance (moisture, coating texture, coating flavor).

QUALITY & FRESHNESS

Notes to be considered when checking quality

- Check both dark and white meat as they deteriorate differently. (White meat generally dries out faster than dark and dark meat generally makes coating go softer faster.)

- When evaluating for moisture of meat cut the product and squeeze with tongs or fingers. However, do not confuse the moisture of the oil in the coating or the skin as moistness of meat.

- A calibrated probe must be used

- Prepare your products for each cook profile that has been developed.

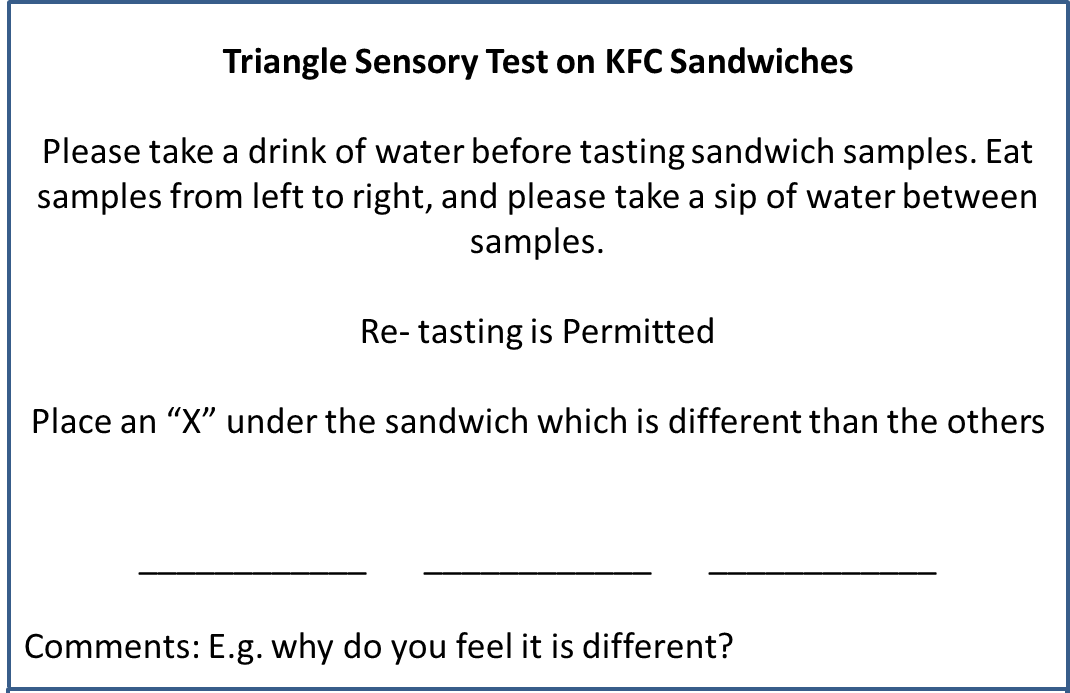

Triangle Sensory Test – Taste

Sensory science is a scientific method used to “measure, analyse, and interpret human responses to products as perceived through their senses of touch, taste, sight, smell, or sound.” Sensory science is often used to improve existing products or to test people’s views on new products, such as the softness of tissues, the crunchiness of an apple variety, or the aroma of air fresheners. It is also used to test the taste and colour acceptance of new products, such as purple ketchup, or the sound characteristics of products, as in the crunch of snack foods.

QUALITY & FRESHNESS

There are many different types of sensory tests. Attribute difference tests ask: How does a certain quality or trait differ between samples? Affective sensory tests ask: What is the consumer acceptance of a product(s)? Overall Difference tests ask: Does a sensory difference exist between samples? A Triangle test is a type of difference test to determine if there is a sensory difference between two products. For example, a researcher may want to see if changing one ingredient in a recipe to make a certain food product will affect the taste of the final product. Or the researcher may want to check the taste after holding the product in a delivery bag for a pre-planned duration. Three coded samples are presented to each panellist, and each panellist is asked to pick out which sample they feel is different from the other two. There are also sensory tests which panellists have to be trained to detect taste thresholds (such as determining the concentration of a flavour which can be identified by the panellist when introduced into a food product) or to have trained panellists describe certain characteristics that researchers are interested in studying.

Sensory tests have to be conducted under controlled conditions to reduce bias (prejudice or influence) on how panellists view the product(s). The sensory room has to be free from distractions (sound, odours) to not influence people’s decisions of the product. Sensory testing laboratories are able to adjust the lighting, air regulation, and individual booths according to the needs of each sensory test that is conducted. Samples also have to be presented in a random order and assigned product codes, such as three-digit sample numbers, to keep food products anonymous to further reduce influencing the panellists’ decision. The sensory test measures if any differences detected are truly significant by analysing the sensory data for statistical significance. After statistical analysis, the researchers can make a meaningful interpretation from the results of the sensory data.

References

Meilgaard, M, Civille, GV, Carr, BT. 1999. Sensory Evaluation Techniques.

3rd ed. Boca Raton: CRC Press LLC.

QUALITY & FRESHNESS

Triangle Sensory test - Administrators Guide

Estimated Preparation Time: 30 minutes

Estimated Activity Time: 1 class period (45 minutes to 1 hour)

Objectives:

- To introduce sensory science to Participants

- To have Participants voluntarily participate in a sensory test

Materials:

- Original Product (total should equal 1.5 times the number of Participants)

-

New Proposed Product (total should be 1.5 times the number of Participants)

Example: If there are 12 Participants in the class you will need at least 18 of the Original Product and 18 of the new proposed product

- Small white paper plates

- Marker

- Sensory ballots (samples are provided)

- 6-8 oz. plastic cups (one for each Participant)

- Water

- Testing Booths to separate the Participants

QUALITY & FRESHNESS

Be aware that some Participants may have food allergies, sensitivities, or dietary restrictions.

Set-up Procedures:

- Using the marker, label the small white plates with random three-digit codes

Example: Random three-digit sample codes:

767 - Original Product sample

189 - Original Product sample

312 - Proposed Product sample

570 - Proposed Product sample

QUALITY & FRESHNESS

Example: Suggested balanced random code presentations:

Participant #1 receives sample order: 767,312,189

Participant #2 receives sample order: 767,312, 570

Participant #3 receives sample order: 767,189,570

Participant #4 receives sample order: 312,189,570

Participant #5 receives sample order: 312,189,767

Participant #6 receives sample order: 570,312,189

Participant #7 receives sample order: 189,570,767

Participant #8 receives sample order: 189, 570,312

Participant #9 receives sample order: 189,767,312

Participant #10 receives sample order:570,767,312

Participant #11 receives sample order:570,767,189

Participant #12 receives sample order:312,570,767

Participant #13 receives sample order the same as Participant #1

And so on…..

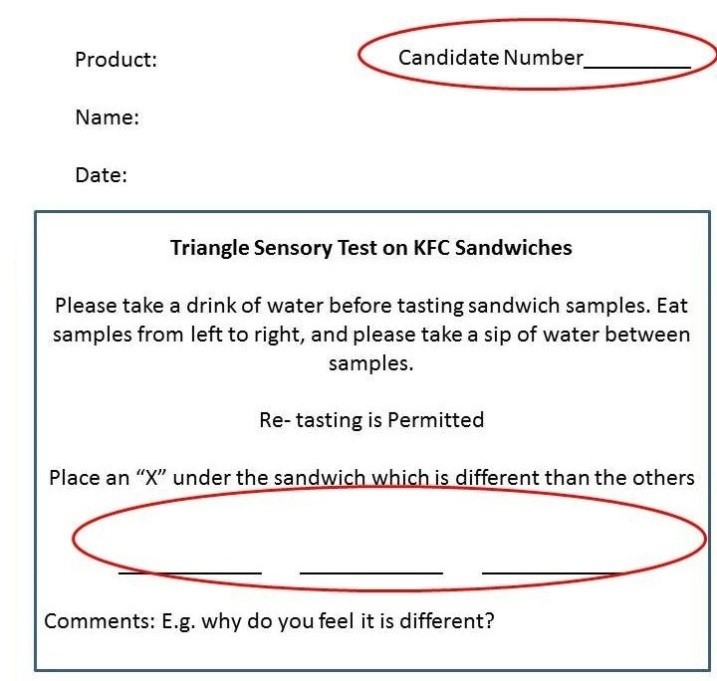

- Prepare a sensory ballot for each Participant.

Photocopy enough ballots for each Participant and write the order for each Participant on the blank lines as shown in the example on the previous page.

QUALITY & FRESHNESS

QUALITY & FRESHNESS

Sensory Test Procedures:

- Introduce the topic of sensory science to familiarize Participants.

- Try not to bias Participants with the introduction. Just mention to Participants that they will be participating in a Triangle sensory test.

- Participants can voluntarily participate, but should not be forced to participate because all sensory tests that include human subjects must be conducted on a voluntary basis. Explain to Participants, if they participate, that sensory panellists have to remain silent during the taste test and cannot share answers with their neighbours. Explain that there will be a discussion after the test to share answers.

- Introduce the experiment to the Participants.

- Mention to Participants that they will be given three Products, and that they should taste the Products from left to right. They should take a sip of water between each sample.

- The object of the test is to mark which of the Products is different from the other two. Only one cookie out of the three should be marked as being different. If Participants have difficulty deciding, mention to them that it is acceptable if they want to go back and forth and re-taste samples to determine the different cookie.

- They may have to re-taste samples, so explain to Participants that they may not want to eat the whole cookie all at once, but wait until the test is over before eating the entire cookie sample.

- If they cannot tell which cookie is different, tell them to guess.

- Use the provided sensory ballot as a guide, if needed.

QUALITY & FRESHNESS

- Begin the experiment.

- Pass out sensory ballots, Products on labelled plates with random codes, and water.

- Allow the Participants to begin the sensory test. Enforce the quiet rule during the sensory test.

- Collect the ballots.

- Tally sensory ballots to determine the number of correct and incorrect responses.

- Have a class discussion with Participants and get their input.

Preparing the Ballot papers

- Determine how many Participant will be attending

- Using the Excel (Participant No) sheet pre fill the ballots with the codes (Circled below)

QUALITY & FRESHNESS

It is important that when the product is brought to the participant that is it in the order of the ballot sheet

Formats for Sensory Testing:

- Triangle Tasting Ballot Tasting Ballot

- Triangle Sensory Test Capture Sheet Sensory Test Capture Sheet

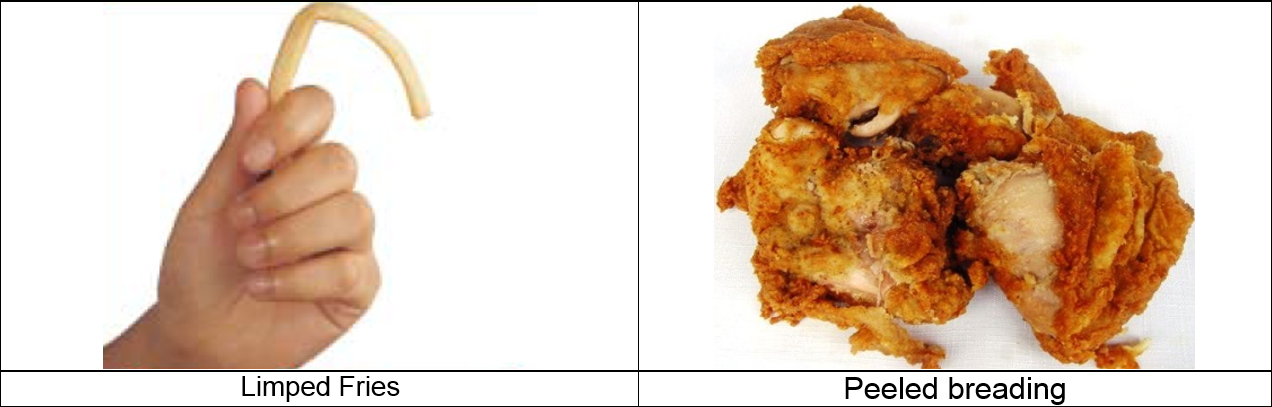

PACKAGING

Product Quality Challenges

Delivery Fundamentals: To deliver - ‘Hot Food Hot & Cold Food Cold’

Must Have’s:

- Heated Pouch

- Product quality monitoring system E.g. “Quality Every Day Assessment”

- Beverages and sides stored chilled and pre-bagged

Measures:

- GES

- CER

Some challenges that you may face as you plan to deliver:

PACKAGING

Other challenges

- Already short packaged shelf life - Fries 7 mins & Burger 10 mins!

- Time & Temperature

‘Moisture’ is essential for good eating Quality but it can also damage products due to improper packaging.

So… what can you do to Improve Product Quality

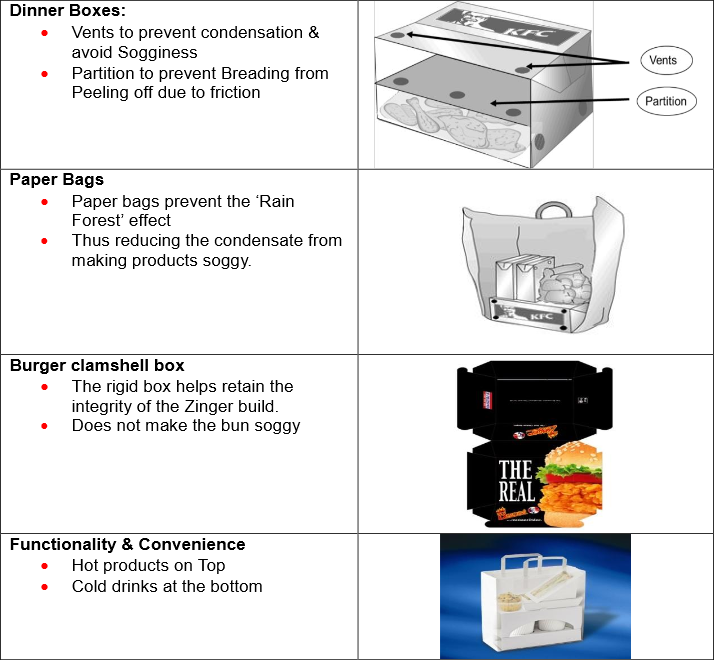

- Improve Packaging - Paper / Vents / Partition / Hot Packs

- Apply Ingredient Technology - Coated Fries

- Include Delivery Friendly Sides - Stronger / Crispier Coatings

- Measuring Quality – Use Daily Quality Check-lists / “P” in CHAMPS & CER

PACKAGING

Defining the right packaging

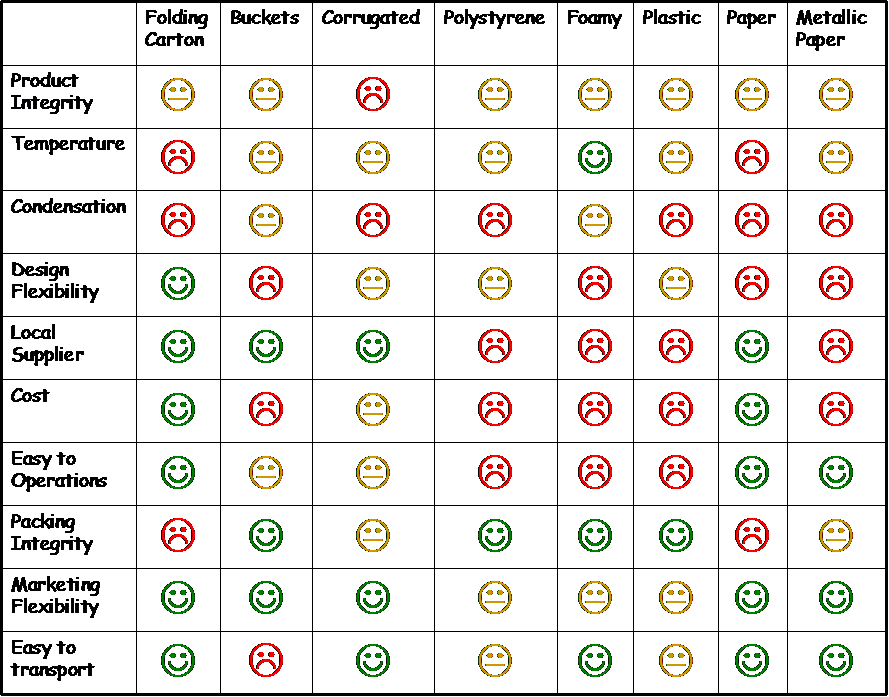

The matrix below defines types of packaging against various parameters like product quality, cost, ease etc. You can have a similar matrix defined for your market for future reference.

PACKAGING

BEST PRACTICES

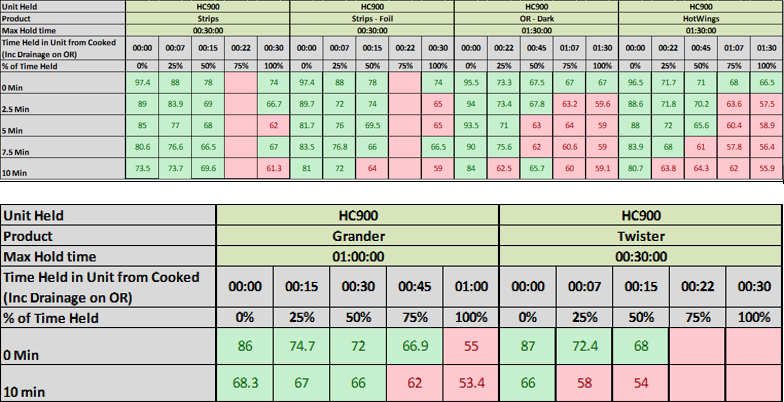

Product Validation Exercise from KFC Central & Eastern Europe (Two Day Session)

Day 1:

The session was focused on generating temperature and product quality data for multiple products within store. The following process was undertaken for each product tested:

- Product cooked in one batch and taken to hot hold. Temperature taken at point of entry

- At intervals in the hot hold (based on current product holding time), the product was taken out and placed into Delivery bag.

- The product was removed from the Delivery bag at intervals to measure temperature and quality.

Specific details of the test were:

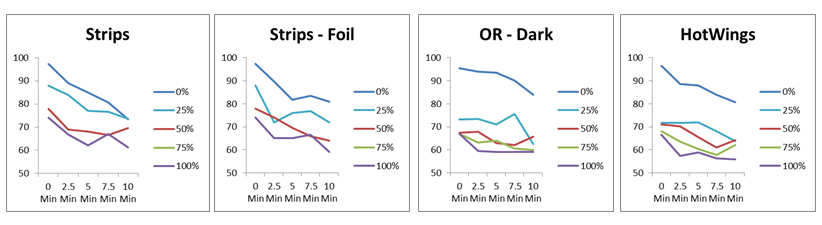

- Products tested – OR chicken, Strips, Strips (with foil packaging), Hot wings (Flat) and two Sandwiches.

- Intervals of hold time in hot hold – 25%, 50%, 75%, 100%

- Time intervals for product testing in Delivery bag (2.5 mins, 5 mins, 7.5 mins and 10 mins)

Conditions for the testing:

- Product held in the bottom half of the HC 900 (Temperature differential of upto 8 C from top half)

- Product packaged separately

- Delivery bags kept in store throughout time of testing

- Products were packed individually into separate heated pouches so that temperature was not lost when opening the bag to take the temperature

BEST PRACTICES

The Validation process can be found in the attached file. Delivery Product Validation

Results – Temperature testing

BEST PRACTICES

Observations – Core meat blocks

Observations

- All Products lost approx. 25-28% of its temperature while being held in the HC900 – bottom half (start to end of hold time)

- Strips packed before 50% of its hold time achieved above 65 degrees at the end of 8 minutes in the pouch.

- At 50% of hold time OR chicken and Hot wings fell below 65 degrees

BEST PRACTICES

Takeaways

- Undertake further testing using meal bundles and holding in various equipment

- Validate the temperature of the equipment holding the product

- Include blind consumer testing Vs fresh in freshly made

Observations – Sandwiches

BEST PRACTICES

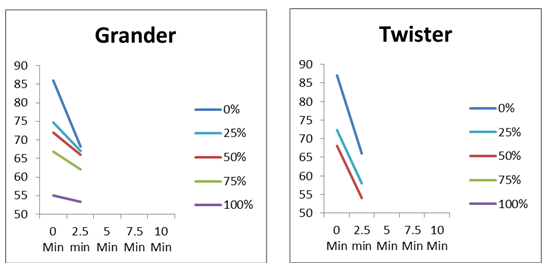

Observations

- Grander – At 50% of hold time the required temperature was achieved at the end of 10 minutes in the heated pouch.

- Twister – At 25% of Hold time the required temperature was not achieved at the end of 10 minutes in the heated pouch

Takeaways

- Validate the temperature of the equipment holding the product

- Include blind consumer testing Vs fresh in freshly made

Day 2: Review and next steps

The day was spent working through the following questions:

The temperature and quality testing showed there is a limited period from product leaving fryer to consumer (either in Hot Hold or packaged travelling to customer). Longer hold time will equate to shorter delivery time and vice versa. What is the commercial sweet spot between the two intervals, ensuring the product quality our consumer receives across all products is to Dine in standard?

- What further testing is required?

- What scenarios do we want to review?

- How do we improve the controlled testing? Can we involve NPD to continue?

- Consumer group blind testing

BEST PRACTICES

Theoretically proving the above system will deliver Dine in standard product is only as good as the reality on the ground. How do you accurately and consistently prove the reality on the ground today? How are you comfortable with compliance going forward? This should cover:

- Do we have sufficient KPIs to measure time from Fryer to consumer at present, so we cannot test whether the theory is being adhered to (and the ones you do have imply that 40% of product reaches the consumer below 65c)

- We don’t know with enough certainty what our consumers are thinking of us (How can we make GES available today (Short term solution)

- What role does CER have?

- Do we have sufficient training materials to support this?

- Is our Trade Zone mapping appropriate for the reality on the Group

How do we define a simple process to manage product in store based on delivery using a different shelf life?

- A standard process that can apply to all stores

- How do we reduce the risk of the team using product that is in time but not delivery time

- How would this look with QPM?

Please refer to the attached presentation and excel sheet for more details:

Product Validation Exercise - KFC CEE Product Validation Exerceise

Product Delivery Testing Results & Format - KFC CEE Product Delivery Testing Results